You may be starting to discover that there are many different types of overhead cranes if you have studied and found that an overhead crane system could enhance the production or material handling procedures at your site. What kind of overhead crane do I need for my business? Maybe the question running through your head as you try to sort through the wealth of information about overhead cranes. The features and setups of overhead cranes can vary greatly. A crane build is never precisely the same again! The optimal crane for your facility or your application might not function in a lifting application or building structure that is similar to yours.

Overhead cranes can be made in a variety of designs to suit a range of industries and uses. The most typical varieties include: Gantry cranes, jib cranes, bridge cranes, workstation cranes, monorail cranes, top-running, and under-running are a few of the overhead cranes.

A Gantry Crane can be the perfect answer for an activity like vehicle production, where extensive lifting materials like car batteries and engine components are required but constrained by a permanent overhead crane installation. Our portable steel workshop gantry cranes are suited for indoor and outdoor use and may be outfitted with electric chain hoists, wire rope hoists, or manual chain hoists.

Semi-gantry cranes are a unique variety of crane that combine an overhead bridge crane's and a motorised gantry crane's designs. An elevated runway acts as the support for one side of a semi-gantry bridge. Benefits include reduced runway costs, fitting without obstruction under larger overhead bridge cranes, Great for building walls that are long and clear of obstructions and can be moved so that a work area's machinery and materials are easily accessible.

Jib cranes are a remarkably flexible solution with three distinct mounting options: Wall Mounted, Column Mounted (Pillar), and Ceiling Mounted. They also include articulated variants for applications that require lifting around structural barriers or corners. The sort of Jib Crane best suited to your operation would depend on your application, such as a workplace with several workstations and no proper supporting structure for a Monorail Crane or Workstation Bridge Crane.

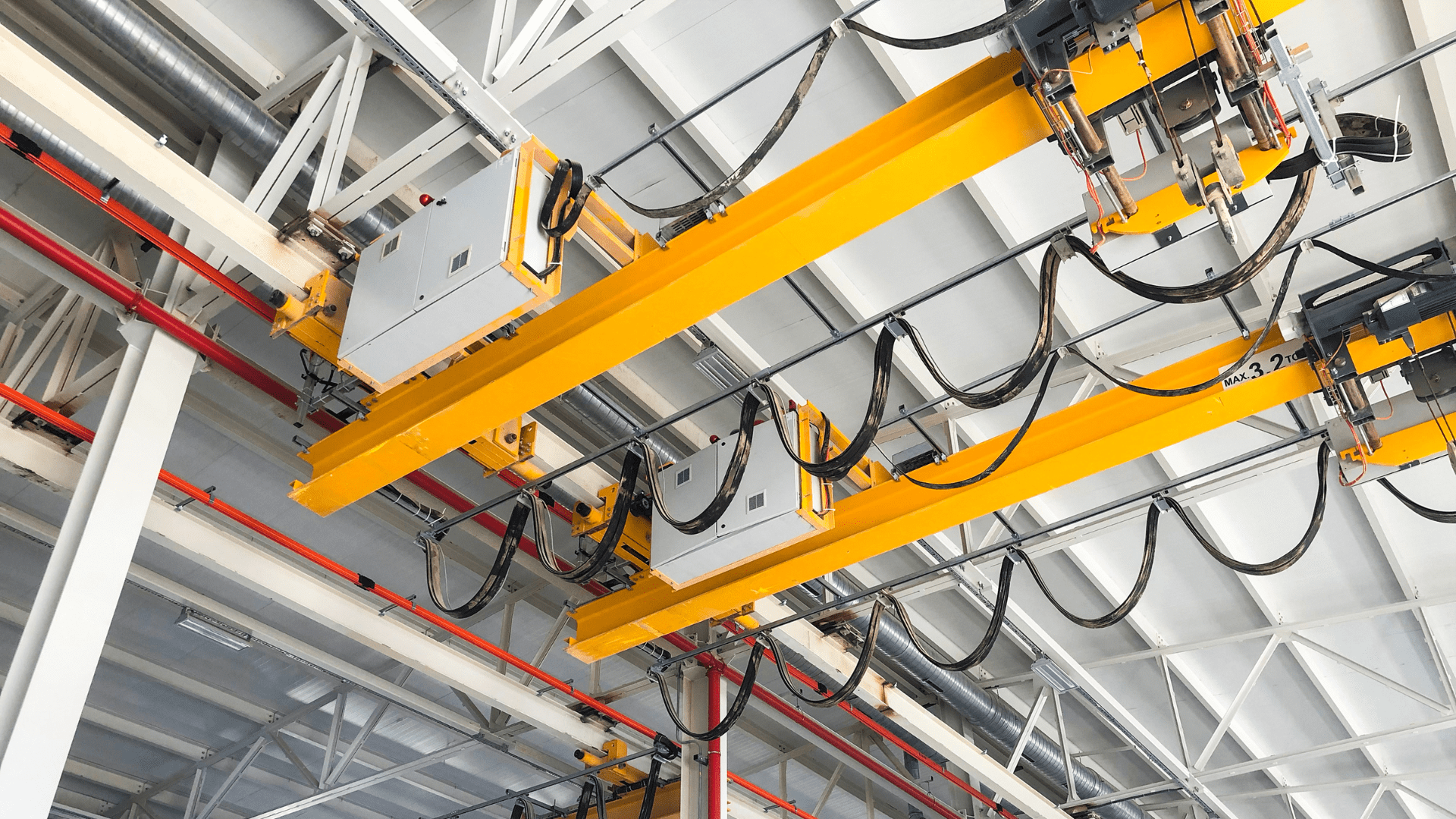

This design of bridge crane runs along the length of a building on an elevated runway system. It is offered with both a single-girder and double-girder bridge configuration. Bridge cranes also move their hooks on three different axes. This enables the flexibility to position and set loads with extreme care.

A workstation bridge crane often allows the operator to move the hoist left and right on the bridge and the single-girder bridge beam forward and backward in a single-girder design. Thanks to its modular design, the system may be built up later to grow with your business.

Drive Suppose you have routine or fixed processes in your operation, like a factory line or processing plant, and you need a lifting solution to lift and move loads forward and backward along a beam. In that case, our monorail crane system is a hollow-profile lightweight overhead crane system in a monorail configuration.

Top-running overhead cranes can be constructed to handle weights of any size since they have no limiting capacity. Top-running cranes can be constructed with capacities ranging from less than 1/4 tonne to more than 100 tonnes. These overhead cranes are perfect for carrying heavy items because the runway or building structure supports them.

Under-running overhead cranes have a user-friendly design that offers the utmost versatility for fulfilling all of your production demands. They were created with flexibility and usefulness in mind. Because the bottom flange of the runway beam provides support for the wheels that drive the bridge over the facility, these cranes are also known as underhung cranes.

The number of beams can determine if a crane is a single or double beam. It has the appearance of an EOT crane with a single girder. A single girder crane is used for a brief duration or light labour jobs. It can work for a maximum of 6 hours and has a lifting capacity of 20 tonnes.

Two girders span the span of double-girder EOT cranes. These are tough and can carry huge loads of up to 150 MT on construction sites. They are in great demand in sectors including shipyards, construction sites, and the metal industry. We offer double-girder EOT cranes with cutting-edge designs suitable for various applications.

As diverse as the industry's overhead cranes' service is, so are their general purposes. Typical applications comprise:

Material coils, billets, and sheets require a demanding service cycle, which metal fabricators can handle with hoists. It is necessary to move heavy moulds and parts. Industrial operators use girder cranes to precisely position big machinery. Any size or weight of the load can be managed safely and effectively with overhead cranes.

With components and accessories that are simple to replace, overhead cranes are available in a range of sizes, styles, shapes, and configurations. When moving bulky goods through a production facility, overhead cranes are more efficient and practical than manoeuvring through aisles and floors. Work can be done more quickly, affordably, and safely by installing an overhead crane to leverage the factory's overhead area. Several sizes, forms, and designs are available for overhead cranes. There is a specific kind for every application's requirements.